News

When Every Load Matters: Smarter Dump Bodies Are Quietly Changing Mine Safety

July 1, 2025

Enhancing Mine Safety with Duratray’s Innovative Suspended Dump Body Solution

Dump trucks are central to opencast or surface mining. Every day, they shift massive volumes of rock and ore across challenging terrain. But with the routine nature of the work come serious risks.

Issues like driver fatigue, body vibration, noise exposure, material sticking inside the tray, and cleaning injuries still happen all too often. And when something does go wrong, the consequences can be life-altering—or worse.

That’s why more mines are moving towards practical innovations like the Duratray Suspended Dump Body (SDB). It’s not a flashy add-on or a trend. It’s a thoughtfully engineered product that addresses some of the persistent problems in mining haulage, the kind that don’t always make headlines but cause countless incidents.

What Really Causes Fatigue in the Cab

Operating a haul truck might look simple from the outside, but inside the cab, it’s another story. Drivers put in long hours, often on overnight shifts, on repetitive routes, and in harsh conditions. Staying focused for the entire shift isn’t easy, especially when the equipment works against you.

Vibration Wears You Down

The jolts and shakes from rough haul roads aren’t just annoying. Over time, they affect the driver’s body and concentration. Traditional steel trays don’t absorb any of this movement—every knock during loading, every bump in the road, is transferred into the seat.

Duratray’s suspended design absorbs much of that shock. This reduces how much vibration reaches the driver. In testing, trucks fitted with the SDB showed vibration levels far below those recorded with conventional steel bodies. This means drivers can remain more comfortable and alert, especially in high-pressure parts of their shift.

Noise Takes Its Toll

Cabin noise is a constant stressor. Many operators report cabin noise levels that go beyond what’s considered safe for extended exposure. Over time, this drains mental energy and affects focus.

Trucks using Duratray bodies have shown a noticeable drop in in-cab noise. While this doesn’t eliminate the problem entirely, it’s a meaningful step towards reducing the mental load on drivers during long shifts.

Why Carryback Isn’t Just an Efficiency Problem

Not all of the material in the tray comes out during dumping. Some of it sticks. This leftover load is called carryback—and it causes more problems than people realise.

Each return trip with carryback wastes fuel. It also adds wear on tyres and components. But more worryingly, it creates imbalance. A load that isn’t evenly distributed can shift unexpectedly. This puts the truck at greater risk during travel and tipping.

Manual removal of carryback is another concern. Workers often have to get inside the tray or work beneath it while it’s raised. Both tasks are risky, and unfortunately, these kinds of jobs have led to serious injuries across multiple mine sites.

The design of the Duratray SDB makes a big difference here. Its surface doesn’t allow material to stick easily. Operators consistently report that loads empty cleanly, with almost no residual material left behind. This removes the need for most cleaning interventions and helps prevent the kinds of unpredictable shifts that have caused incidents in the past.

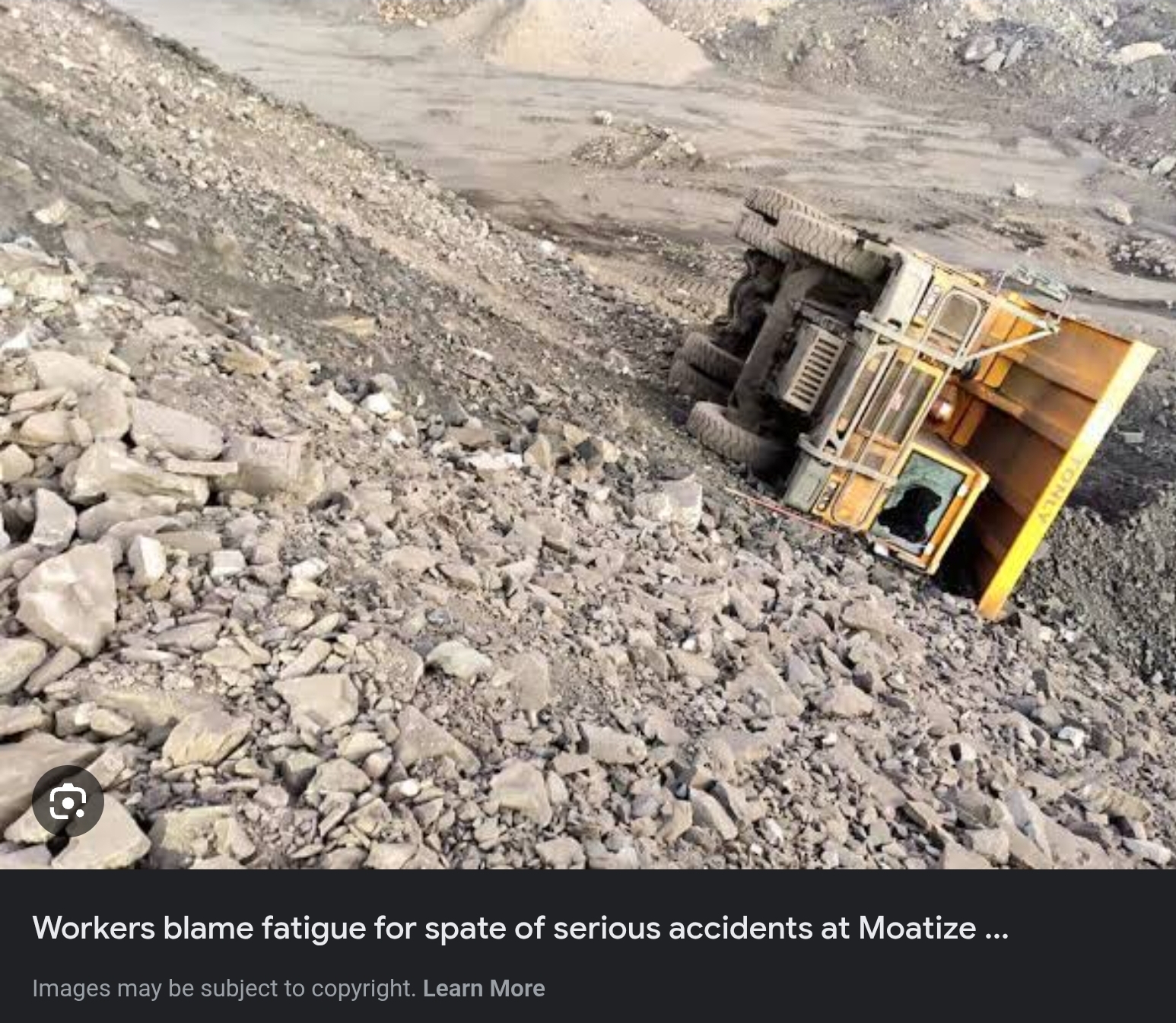

What the Past Has Taught Us: Global Incidents That Could Have Been Avoided

These aren’t abstract risks. The mining world is full of real stories that show what happens when fatigue, vibration, noise, and carryback are left unchecked.

- Chile, 2019: A haul truck rolled while descending a ramp at a copper mine. The investigation suggested that the driver may have lost control due to fatigue and shifting load material that hadn’t fully discharged. Tragically, the driver was killed.

- Queensland, Australia, 2021: A truck ran into a parked loader during a night shift. The driver had nodded off at the wheel. Vibration and lack of sleep were seen as contributing factors.

- Rustenburg, South Africa, 2020: A worker suffered serious injuries while clearing hardened ore from inside a raised steel dump body. The failure of a component caused the body to collapse during the cleaning task.

- Ontario, Canada, 2018: A truck tipped while offloading at a gold mine. Residual material in the tray shifted during tipping, throwing off the balance of the vehicle.

- Nevada, USA, 2022: A near-miss occurred when an operator momentarily lost concentration. He later reported that the noise in the cab was constant and mentally exhausting.

Each of these events is a sobering reminder. Many of the contributing factors were preventable, and better equipment design might have made the difference.

One Change, Several Gains

What sets the Duratray SDB apart isn’t one big feature. It’s the way it addresses several root issues at once.

Vibration is significantly reduced, allowing drivers to stay fresher for longer. Cabin noise drops, which helps with concentration. Carryback is practically eliminated, meaning fewer cleaning tasks and more consistent loads. On top of that, some mines have recorded fuel savings and higher payloads, since there’s less dead weight coming back from the dump zone.

Rather than focus on just one aspect of performance, the Duratray SDB supports safety, comfort, and efficiency together—without the need for expensive system overhauls or major training changes.

Shifting the Conversation: From Output to Safety

Too often, mining equipment is discussed in terms of productivity alone. How many tonnes can be moved per shift? How fast can it go? How durable is it?

But safety and productivity aren’t separate goals. Safer equipment leads to fewer incidents, less downtime, and more reliable operations. The Duratray SDB shows that you don’t have to choose between protecting your people and hitting your targets. You can do both—if you’re using the right equipment.

Final Thoughts

Working in mining means understanding risk. But not all risks are part of the job. Some come from using outdated tools or not questioning long-standing practices. Dump truck safety has improved over the years, but there’s still work to do.

Solutions like the Duratray SDB don’t make headlines. They do something better: they make life safer and easier for the people who rely on their trucks to get the job done, shift after shift.

For any mine looking to cut downtime, improve operator welfare, and reduce incidents without slowing down operations, this is one piece of equipment worth looking into.