News

Superior Asset Integrity: The Critical 2026 Chassis Preservation System Mandate

February 18, 2026

Table of Contents

- Executive Summary

- 1.0 The Rigidity Trap: Moving Beyond Static Efficiency

- 1.1 The Failure of Computational Authority

- 2.0 The Physics of Operation: Viscoelastic Hysteresis

- 2.1 Elasticity vs. Hysteresis

- 3.0 Engineering Asset Longevity: Fatigue Mitigation Architecture

- 3.1 The Financial Cost of Fatigue

- 4.0 Health, Safety, and the Human Element: ISO 2631

- 4.1 Bio-Mechanical Isolation

- 5.0 Future-Proofing for Autonomy: The AHS Mandate

- 5.1 Lowering the Sensor Noise Floor

- 6.0 Operational Yield: Eliminating Parasitic Loads

- 6.1 The Cost of Carryback

- 7.0 Modular Asset Sustainment: A New Maintenance Philosophy

- 7.1 Cold Work vs. Hot Work

- 8.0 Global Market Realignment: Regional Imperatives

- 8.1 Africa: The High-Growth Frontier

- 8.2 North America: The Autonomy Hub

- 8.3 Australia: Core Market Optimisation

- 9.0 Conclusion: The Necessary Evolution

- 10.0 Step Into the 2026 Mandate: Protect Your Most Valuable Asset

Executive Summary

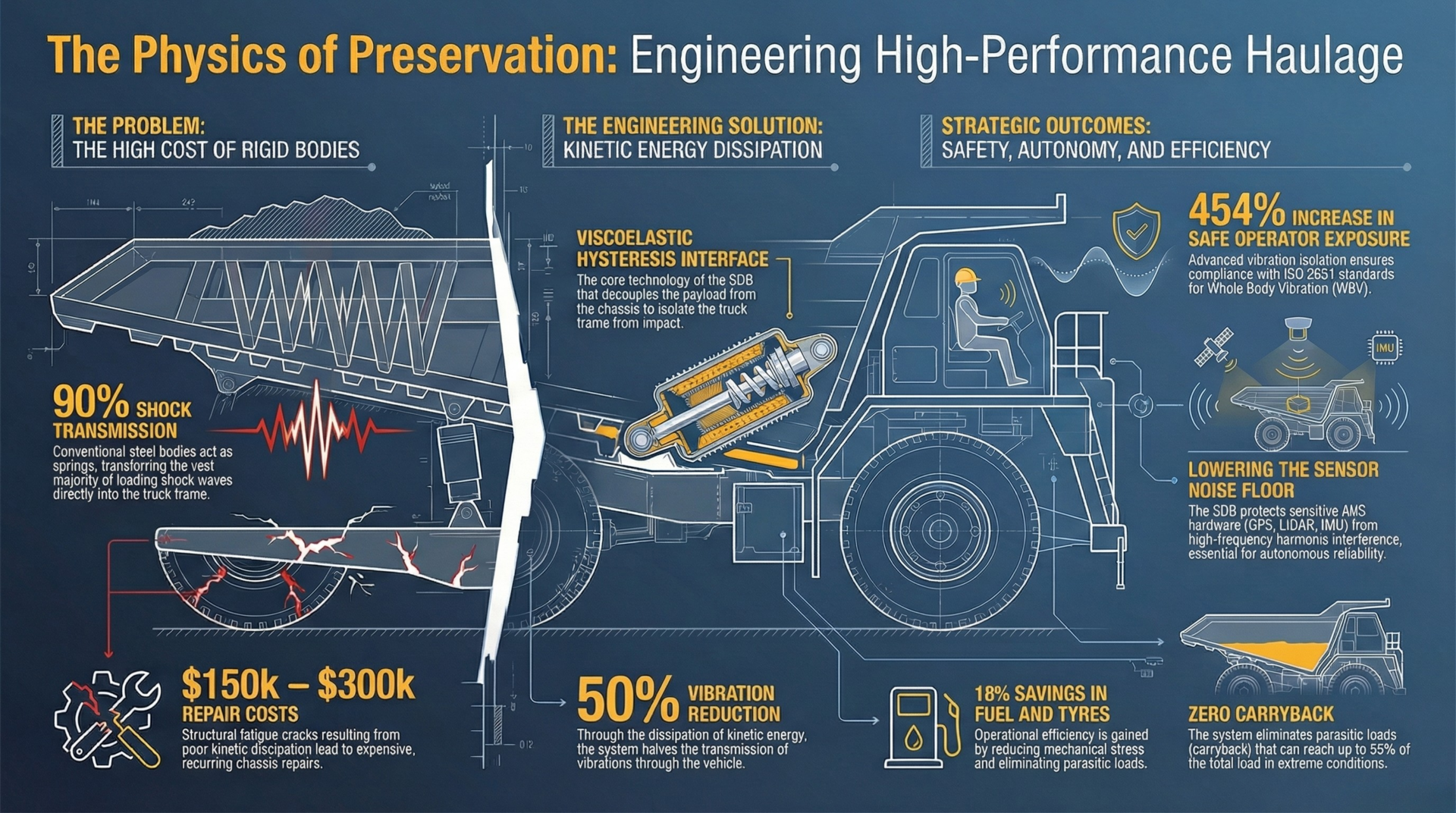

As the global mining sector undergoes a fundamental structural transition toward Autonomous Haulage Systems (AHS) and stringent ESG mandates, the role of the dump body has evolved. It is no longer a passive “container” but a critical Chassis Preservation System. This executive summary outlines the engineering imperatives for the 2026 operational landscape, focusing on the preservation of the fleet’s most valuable asset: the truck frame.

- Asset Lifecycle Extension: Traditional rigid steel bodies act as conduits for high-frequency shock waves, transmitting over 90% of loading impact directly to the truck frame. This accelerates structural fatigue, leading to cracks that typically cost between $150,000 and $300,000 per repair intervention.

- Kinetic Energy Dissipation: Utilising a Viscoelastic Hysteresis Interface, the Suspended Dump Body (SDB) decouples the payload from the chassis. This converts kinetic energy into low-grade thermal energy, reducing peak vibration transmission by up to 50%.

- Bio-Mechanical Isolation: The system delivers a scientifically validated 454% increase in safe operator exposure time. This ensures Tier 1 compliance with ISO 2631 standards for Whole Body Vibration (WBV), which is essential for workforce health and retention.

- AHS Optimisation: By significantly lowering the Sensor Noise Floor, the SDB protects sensitive GPS, LiDAR, and IMU hardware from high-frequency harmonic interference. This is a prerequisite for maintaining autonomous fleet reliability and operational velocity.

- Operational Yield: The technology eliminates Parasitic Loads (carryback), which can consume up to 35% of effective payload in high-clay environments, delivering up to 18% savings in fuel and tyre wear.

1.0 The Rigidity Trap: Moving Beyond Static Efficiency

For decades, the mining industry has been constrained by a “static efficiency” trap. Engineering focus has traditionally been narrow: maximise the volume of the steel box to maximise the payload. However, this approach ignores the dynamic reality of a 400-tonne machine operating in high-impact environments. Conventional steel bodies operate on simple principles of elasticity; like a giant spring, they store and release impact energy directly into the truck chassis.

In the 2026 operational mandate, “carrying dirt” is no longer the primary KPI for the haulage fleet. The focus has shifted to Asset Management and Capital Expenditure (CapEx) Protection. The transition from a simple haulage attachment to a Suspended Load Isolation System represents a move toward precision engineering where the dump body acts as the “sacrificial guardian” for the fleet’s most valuable asset: the chassis.

1.1 The Failure of Computational Authority

Many industry participants rely heavily on Discrete Element Method (DEM) simulations to justify thinner, “V-profile” steel floors. While DEM is useful for predicting material flow, it often fails to account for the long-term structural degradation of the host asset. This reliance on “computational authority” creates a false sense of security regarding structural integrity.

In contrast, the SDB’s engineering foundation is built on Empirical Field Validation and the Analytic Hierarchy Model. By measuring real-world stress cycles on the chassis at sites globally—from the Pilbara to the High Andes—it has been proven that “rigid efficiency” is a myth that eventually leads to catastrophic frame failure and multi-million dollar asset write-offs.

2.0 The Physics of Operation: Viscoelastic Hysteresis

The core technical advantage of the SDB lies in its Viscoelastic Hysteresis Interface. To understand why this is superior to steel fabrication, one must look at the molecular level of energy transfer.

2.1 Elasticity vs. Hysteresis

When a 50-tonne boulder impacts a steel floor, the steel deforms elastically and immediately snaps back, sending a destructive shock wave through the hoist cylinders and into the frame. This is known as the “anvil effect”.

The SDB utilises a Dynamic Catenary Suspension—a high-performance elastomeric mat suspended over a Structural Space Frame. When the load impacts the mat, the elastomer undergoes hysteresis. The molecular chains within the rubber slide past each other, creating internal friction that converts kinetic energy into heat rather than structural vibration.

This Peak Force Truncation smooths the force-time curve of the impact. Instead of a sharp, destructive spike of energy, the chassis experiences a managed, low-frequency wave. By the time the energy reaches the frame, its destructive potential has been attenuated by up to 50%.

3.0 Engineering Asset Longevity: Fatigue Mitigation Architecture

The primary enemy of a mining truck is fatigue. Every loading cycle, every bump on the haul road, and every dump cycle contributes to the cumulative fatigue of the chassis.

3.1 The Financial Cost of Fatigue

A standard Tier 1 mining truck represents an investment of $5,000,000 to $10,000,000. When the chassis develops fatigue cracks, the asset must be removed from the line.

- Direct Repair Costs: Specialised welding, NDT (Non-Destructive Testing), and structural reinforcement typically range from $150,000 to $300,000.

- Opportunity Cost: The loss of production during the 14–21 days of repair can exceed $1,000,000 in lost revenue.

By implementing a Fatigue Mitigation Architecture, the SDB extends the mean time between failures (MTBF) for the chassis. This is not merely an incremental improvement; it is a fundamental shift in the Total Cost of Ownership (TCO).

4.0 Health, Safety, and the Human Element: ISO 2631

While mechanical preservation is vital, the biological preservation of the operator is a legal and ethical mandate. Whole Body Vibration (WBV) is one of the leading causes of long-term disability in the mining sector.

4.1 Bio-Mechanical Isolation

Data from independent field studies, including those conducted at Mt Keith and Moolarben, show a staggering difference in vibration profiles.

- Rigid Steel Body: Average vibration levels often hover around 0.811 m/sec², approaching or exceeding the ISO 2631 “caution zone” within a few hours.

- Suspended Dump Body: Vibration levels are typically reduced to 0.258 m/sec².

This reduction equates to a 454% increase in the time an operator can safely remain in the cab before hitting the daily exposure limit. In an era of labour shortages and rising insurance premiums, providing this level of Bio-Mechanical Isolation is a significant competitive advantage for mine operators.

5.0 Future-Proofing for Autonomy: The AHS Mandate

The acceleration of Autonomous Haulage Systems (AHS) has fundamentally changed the physical requirements of the dump body. An autonomous truck is essentially a precision robot on wheels, carrying millions of dollars in sensitive electronic hardware.

5.1 Lowering the Sensor Noise Floor

The sensors that drive AHS—LiDAR, Radar, GPS, and high-precision IMUs—are highly sensitive to vibration. High-frequency harmonics from a rigid steel tray create a high Sensor Noise Floor, which can lead to:

- Data “jitter” and phantom obstacle detection.

- Premature failure of solder joints in electronic control units (ECUs).

- Frequent recalibration requirements for optical sensors.

The SDB provides Harmonic Isolation, acting as a mechanical low-pass filter. By decoupling the “brain” of the truck from the violence of the “body”, the SDB ensures that AHS fleets can operate at peak velocity with higher reliability. We do not compete with the OEM’s autonomy package; we provide the stable platform that allows it to function as intended.

6.0 Operational Yield: Eliminating Parasitic Loads

Efficiency in 2026 is defined by the net yield of every haul cycle. One of the most significant drains on efficiency is the phenomenon of carryback.

6.1 The Cost of Carryback

In high-clay or “sticky” environments, material adheres to the corners and floors of rigid steel bodies.

- Parasitic Load: This “dead weight” can account for 10% to 35% of the total payload capacity.

- Fuel Burn: The truck consumes fuel and wears out tyres to transport waste material back and forth between the pit and the crusher.

The SDB’s floor is inherently flexible. During the dump cycle, the mat flexes and changes shape, breaking the vacuum seal of sticky material. This Active Material Ejection ensures a clean dump every time, maintaining carryback at virtually 0%.

7.0 Modular Asset Sustainment: A New Maintenance Philosophy

Traditional steel bodies require a “patch and weld” maintenance philosophy. This involves frequent “hot work,” which introduces heat-affected zones (HAZ) into the structure, potentially weakening it further.

7.1 Cold Work vs. Hot Work

The SDB moves the industry toward Modular Asset Sustainment.

- Maintenance Cycle: While a steel liner may need replacement every 9 months, an SDB rubber mat typically lasts 35 to 40 months.

- Replacement Speed: Replacing a mat is a “cold work” process that can be completed in 24 to 48 hours.

- Resource Efficiency: This eliminates the need for intensive welding teams and the associated safety risks of fire and toxic fumes in the workshop.

8.0 Global Market Realignment: Regional Imperatives

The “Chassis Preservation Mandate” is not a one-size-fits-all solution; it is tailored to specific regional challenges as part of a 2026 global realignment.

8.1 Africa: The High-Growth Frontier

With a projected 6.6% CAGR in mining value, Africa is a priority market. The combination of remote sites, difficult-to-handle materials, and the need for extreme asset longevity makes the SDB the logical choice for African gold and copper operations where “uptime” is the primary currency.

8.2 North America: The Autonomy Hub

In regions like Nevada and the Canadian oil sands, the focus is on Brownfield Autonomy Retrofits. The SDB serves as the physical firewall for autonomous sensors on older chassis, protecting the investment in new technology.

8.3 Australia: Core Market Optimisation

In the Pilbara and Bowen Basin, the SDB’s ISO 2631 compliance is a mandatory tool for “Zero Harm” initiatives. Furthermore, the elimination of parasitic loads in iron ore and coal applications directly supports the decarbonisation goals of the major miners.

9.0 Conclusion: The Necessary Evolution

The dump body is no longer a passive component. It is a Chassis Preservation System that determines the biological safety of the operator, the mechanical integrity of the truck, and the data accuracy of the autonomous brain.

By anchoring our engineering in the scientifically validated metrics of Viscoelastic Hysteresis, Peak Force Truncation, and Asset Lifecycle Extension, the mining industry can move beyond the commodity trap of steel fabrication. The SDB is the evolution required to realise the full potential of billion-dollar investments in autonomy and sustainability.

10.0 Step Into the 2026 Mandate: Protect Your Most Valuable Asset

The era of the “static efficiency” trap is over. In a mining landscape now defined by Autonomous Haulage Systems (AHS) and stringent ESG mandates, the dump body can no longer be a passive container; it must be a proactive Chassis Preservation System. With Tier 1 mining trucks representing a capital investment of up to $8,000,000, the transition to a Suspended Load Isolation System is the only way to safeguard your fleet’s structural integrity.

Don’t let your chassis become an anvil. Take the next step towards operational excellence:

- Audit Your Repair Costs: Traditional rigid bodies transmit over 90% of loading impact to the frame, leading to fatigue cracks that cost between $150,000 and $300,000 per intervention. We can help you calculate the TCO shift for your specific site.

- Prioritise Operator Health: Ensure ISO 2631 compliance and a 454% increase in safe operator exposure time through scientifically validated bio-mechanical isolation.

- Stabilise Your AHS Fleet: Lower your Sensor Noise Floor to protect sensitive GPS, LiDAR, and IMU hardware from destructive high-frequency harmonics.

- Eliminate Parasitic Loads: Recover up to 35% of your effective payload by switching to a flexible floor that maintains carryback at virtually 0%.

Whether you are optimising for Zero Harm in Australia, seeking uptime in Africa, or managing autonomy retrofits in North America, the Suspended Dump Body (SDB) is the evolution required to realise the full potential of your billion-dollar investments.

Reach out to your local Duratray Country Manager today.