News

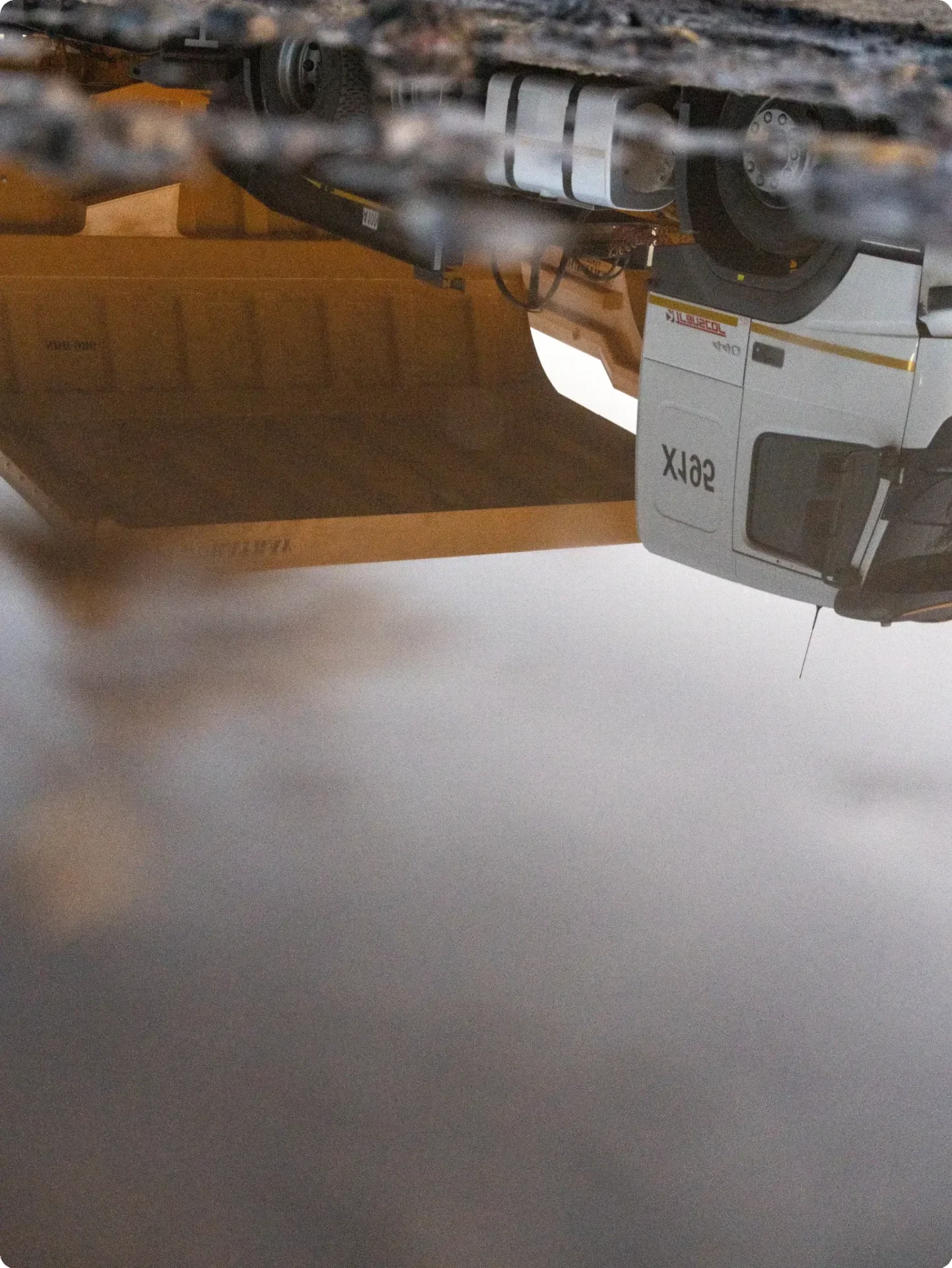

Suspended Dump Bodies in Hard Rock Mining: The Definitive Guide to Proven Performance and Cost Savings

October 30, 2025

Introduction: Shattering the Misconception in Hard Rock Mining

In the intensely demanding world of hard rock mining, a persistent and costly misconception often dictates equipment choices: the belief that Suspended Dump Bodies (SDBs) lack the robustness for extreme conditions. The prevailing myth suggests that only traditional, rigid steel trays can survive the brutal impact of massive, blocky material and the relentless abrasion of the planet’s toughest ores.

This article dismantles this myth with irrefutable, data driven evidence. The reality, proven over decades by the world’s most successful mining operations, is that Suspended Dump Bodies are not just suitable for hard rock mining; they are often the superior choice for driving operational efficiency, reducing maintenance downtime, and lowering total cost of ownership.

We will explore the fundamental engineering principles that give SDBs their edge and present a comprehensive global portfolio of case studies from iconic mines that have standardised on this technology. The evidence clearly demonstrates that the suitability of SDBs for challenging environments is not a matter of opinion, but one of documented historical performance across multiple continents and commodity types.

The Engineering Superiority of Suspended Dump Bodies: A Design Built for Dynamics, Not Just Strength

Understanding why SDBs excel requires a shift from a static to a dynamic mindset. A conventional mining haul truck body is essentially a rigid structure. When a fifty tonne load of granite or copper ore is dumped, the immense impact forces travel unimpeded through the steel liners, into the welds and frame, and directly into the truck’s chassis and suspension system. This results in a vicious cycle of metal fatigue, crack propagation, and accelerated wear.

The Suspended Dump Body, in stark contrast, is a system engineered for intelligent energy management. Its core innovation is a flexible, high strength rubber mat, suspended by an array of precisely calibrated steel ropes, functioning as a multi point, macro scale shock absorber. This foundational design delivers four critical and interconnected advantages in a hard rock mining environment:

- Dramatic Impact Force Reduction and Enhanced Asset Longevity: Independent studies from major mines like Mount Keith have documented reductions in load induced G forces by 40% to 52%. This is a transformative figure. By cushioning the dump impact, the SDB decouples the payload’s destructive kinetic energy from the truck’s vital structures. This directly translates to several key benefits:

- Extended Truck Frame Life: Significantly reduced stress fatigue on the main frame and critical welds, postponing costly major rebuilds.

- Preserved Suspension Systems: Less shock loading on hydraulic cylinders and other components, leading to fewer failures.

- Higher Residual Value: A truck that has operated with a Suspended Dump Body often suffers less structural damage, thereby maintaining a higher resale or trade in value.

- Improved Operator Environment: A significant reduction in cabin noise and vibration, contributing to reduced operator fatigue and enhanced safety.

- Payload Specific Engineering for Maximum Durability: It is a critical misconception that a Suspended Dump Body is an off the shelf product. In reality, its design is a precise calculation based on the density of the haulage material and many other factors. For high density hard rock, the entire system is engineered accordingly from the ground up:

- Heavy Duty Suspension Ropes: Increased thickness, superior grade, and greater quantity to handle the immense weight and dynamic forces.

- Reinforced Rubber Mat: Higher tensile strength and specific compound formulation designed for exceptional abrasion resistance and tear strength.

- Robust Tray Skeleton: The size, mass, and construction of the steel frame are all fortified to provide a solid foundation. This meticulous customisation ensures that when loaded to its maximum rated capacity, the loaded kit never bottoms out or contacts the truck’s frame, guaranteeing structural integrity under the most severe loads.

- Elimination of Liner Damage and Associated Downtime: The flexible mat of a Suspended Dump Body is fundamentally immune to the denting and plastic deformation that plague steel liners. This single characteristic eliminates the entire costly cycle of impact damage, repair, and re-welding; a process that can immobilise a mining haul truck for days or even weeks.

This also removes the inherent safety risks associated with hot work in a mining environment.

- Superior Material Release and Minimal Carryback: The active recoil of the mat during the dumping cycle provides a positive ejection force for the payload. This dynamic action is highly effective in preventing sticky, cohesive materials from binding in the tray. Numerous independent trials by blue chip mining companies confirm a radical reduction, and often complete elimination, of carryback.

This boosts effective payload per cycle, enhances haul road safety by reducing dangerous spillage, and completely eliminates the unproductive downtime of manual clean out.

Global Proof: In Depth Case Studies of Suspended Dump Bodies in the World’s Toughest Mines

The engineering theory is compelling, but the most powerful evidence comes from the mines themselves. These are long term, fleet wide adoptions by recognised leaders in the global mining industry.

- Argyle Diamond Mine, Australia: The Abrasive Giant

- Ownership and Commodity: Previously operated by Rio Tinto, the Argyle mine was the world’s largest diamond producer by volume, renowned for its exceptionally hard and abrasive lamproite ore body.

- Suspended Dump Body Application and Documented Performance: Argyle stands as a monumental case study for SDB endurance. The mine manager publicly stated that the harsh conditions made the decision to purchase SDBs a necessity. In this punishing environment, Argyle operated a fleet of 15 Suspended Dump Bodies for over 20 years. This two decade service life is a definitive rebuttal to any claims of unsuitability.

- Diavik and Ekati Diamond Mines, Canada: Endurance in Extreme Cold

- Ownership and Commodity: Both Rio Tinto operated mines (Diavik and the former Ekati mine) are located in the remote Canadian subarctic, where temperatures plummet to minus forty degrees Celsius.

- Suspended Dump Body Application and Documented Performance: These mines have utilised SDBs for 22 and 18 years respectively. This demonstrates the technology’s resilience not only to hard rock impacts but also to extreme climatic challenges which can embrittle materials. The long term reliability of the Suspended Dump Body system in such a logistically complex environment underscores its engineering integrity.

- Gahcho Kué Diamond Mine, Canada: A Modern Benchmark

- Ownership and Commodity: Operated by De Beers Group (a subsidiary of Anglo American) and Mountain Province Diamonds, Gahcho Kué is one of the world’s largest new diamond mines, located in the Northwest Territories.

- Suspended Dump Body Application and Documented Performance: As a newer mine, Gahcho Kué’s adoption of SDBs from the outset is telling. It indicates that for modern, technologically advanced operations, the Suspended Dump Body is considered a standard, viable solution for hard rock haulage in a challenging permafrost environment, continuing the legacy of its Canadian predecessors.

- Catoca Diamond Mine, Angola: An African Success Story

- Ownership and Commodity: One of the world’s largest diamond mines, owned by a consortium including Endiama, Alrosa, and China Sonangol.

- Suspended Dump Body Application and Documented Performance: The successful use of SDBs at Catoca, a major player in the African mining sector, further dispels the myth that they are unsuitable for the continent’s specific conditions. Its operation in a hard rock kimberlite pipe provides yet another data point for global applicability.

- FQM Kansanshi Mine, Zambia: The Copper Powerhouse

- Ownership and Commodity: Owned by First Quantum Minerals (FQM), Kansanshi is Africa’s largest copper mine.

- Suspended Dump Body Application and Documented Performance: After a rigorous trial, FQM made the strategic decision to purchase SDBs. They have been a continuous client for over eight years. This long term commitment from a major, cost conscious miner invalidates regional biases against the technology.

- Karara Iron Ore Mine, Australia: Conquering Abrasion

- Ownership and Commodity: A major magnetite iron ore producer.

- Suspended Dump Body Application and Documented Performance: At Karara, SDBs have been in continuous, successful operation for over 20 years. This longevity in a high abrasion application directly confronts and disproves the notion that Suspended Dump Bodies wear too quickly for such duty.

Optimising Suspended Dump Body Performance: The Non Negotiable Role of Preventative Maintenance

The global evidence for SDB suitability is overwhelming. The root cause for any scepticism is typically not the product itself, but the operational practice surrounding it. The Suspended Dump Body is a precision tool that requires a specific, albeit minimal, preventative maintenance regimen.

The required maintenance protocol is straightforward and designed for minimal operational disruption:

- Monthly Visual Inspections: A simple sub one hour check per vehicle.

- Rope Adjustments: A one hour procedure during scheduled truck services to maintain optimal mat geometry.

- Annual Rope Changes: Typically 1 to 2 ropes per year, a two hour job during a planned service.

- Wear Mat Replacement: A planned event every 3-4 years, taking a small team 2-3 days.

Failure to perform the simple rope adjustments is the most common failure point. Therefore, investing in initial, proper training for maintenance crews is an essential prerequisite to unlocking its full, long term benefits and significant cost savings on maintenance.

Suspended Dump Body vs. Steel Trays: A Direct Comparative Analysis

| Feature | Conventional Steel Tray | Suspended Dump Body (SDB) | Impact on Hard Rock Mining Operations |

|---|---|---|---|

| Impact Handling | Transfers force directly to structure | Absorbs 40% to 52% of impact force | SDB preserves truck health; steel accelerates structural wear and tear. |

| Liner Maintenance | Frequent welding/replacement (3 days-3 weeks downtime) | Virtually eliminated; mat is non-denting | SDB drastically reduces unplanned downtime, increasing asset utilisation. |

| Carryback | Significant, requiring mechanical clean-out | Minimal to zero | SDB increases effective payload per cycle and improves site safety. |

| Design Philosophy | Static strength, one-size-fits-all | Dynamic, material-specific engineering | SDB is a customised solution; steel is a compromise. |

| Long Term OPEX | High (consumables, labour, fuel) | Proven to be significantly lower | SDB offers a superior Return on Investment (ROI). |

Frequently Asked Questions (FAQ)

- Are Suspended Dump Bodies really suitable for hard rock mining? Yes, absolutely. This is a common misconception. Suspended Dump Bodies have a proven track record in some of the world’s most challenging hard rock mines, including Argyle (Australia), Diavik (Canada), and Kansanshi (Zambia), with documented service lives exceeding 20 years in these environments. Their design is specifically calculated for high density materials.

- What is the most common reason for SDB performance issues? The primary cause is almost always a failure to perform the minimal, scheduled preventative maintenance, particularly the simple one hour rope adjustments. When the system’s geometry is not maintained, performance can be compromised. This is an operational issue, not a design flaw.

- How does the maintenance cost of an SDB compare to a steel tray? The long term operational expenditure(OPEX) for an SDB is proven to be significantly lower. While steel trays incur high costs from liner replacement, welding consumables, and associated labour during frequent downtime, SDBs require minimal routine maintenance and have no liners to weld.

The cost per tonne over the asset’s life is typically lower with an SDB.

- Can SDBs handle large, blocky rock (e.g., 1000mm)? Yes, modern Suspended Dump Body designs are engineered to handle large, blocky material. While specific size acceptance depends on the custom design, newer SDB models are capable of carrying rocks up to 1000mm in size. The flexible mat and suspension system are actually more forgiving than steel when loading large boulders.

- We have a trolley assist system. Is there any benefit to using SDBs? Yes. The lighter tare weight of an SDB compared to a steel tray can contribute to lower energy consumption per cycle when operating on a trolley assist system. Furthermore, the reduced carryback means the truck is not hauling excess weight, optimising the efficiency gains provided by the trolley infrastructure. Some mines report significant fuel and energy savings from this combination.

Conclusion: The Future of Hard Rock Haulage is Intelligent by Design

The collective, long term testimony from Argyle, Diavik, Ekati, Gahcho Kué, Catoca, Kansanshi, and Karara forms an unassailable, evidence based argument. These sites represent the absolute pinnacle of hard rock mining challenges.

The narrative that Suspended Dump Bodies are unsuitable for hard rock mining is a demonstrable fallacy, conclusively dispelled by decades of documented performance. The SDB is a precision engineered system that, when correctly specified and maintained, delivers unparalleled operational advantages: extended equipment life, drastically reduced maintenance downtime, lower operating costs, and enhanced site safety.

For mining professionals focused on improving operational efficiencies and achieving a lower total cost of ownership, the evidence is clear. The future of efficient, cost effective hard rock haulage lies in embracing the intelligent, dynamic, and proven strength of the Suspended Dump Body.

For anyone looking to improve their fleet without locking themselves into one truck brand, Duratray offers a practical, proven, and remarkably smart solution.

Disclaimer

The performance data and case studies referenced are from specific operational trials. Actual results may vary based on site conditions, material characteristics, and equipment configuration. This information is for illustrative purposes and does not constitute a performance guarantee. It is the responsibility of the reader to conduct their own technical assessments with Duratray and validate the suitability and safety of any equipment for their specific application. Duratray International disclaims all liability for reliance on this information.

7 Ways Duratray’s Game-Changing Maintenance Keeps Remote Mines Operational