News

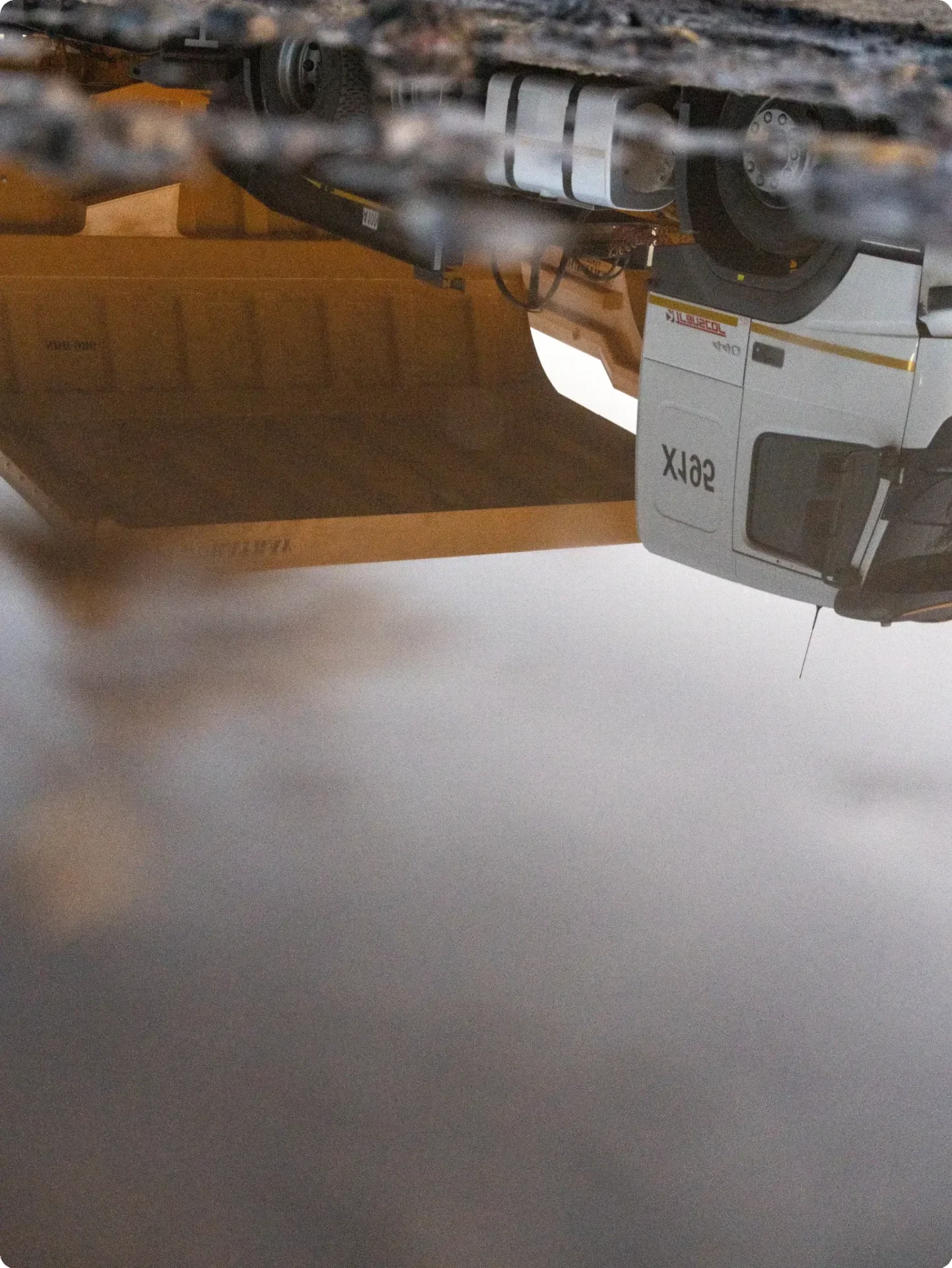

Suspended Dump Body Innovation: Duratray’s Precision Engineering Philosophy for Mining Efficiency

July 29, 2025

In the demanding world of mining, where machines endure punishing conditions daily, equipment must do more than survive – it must excel. The Duratray Suspended Dump Body (SDB) stands apart, not simply as a component in the haulage chain, but as a carefully engineered system designed to enhance performance, increase safety, and improve sustainability from the ground up.

At the heart of its design lies a precision engineering philosophy – one that reimagines the dump body as an intelligent, active contributor to productivity, rather than a passive steel container. For Duratray, every curve, joint, and material choice serves a calculated purpose, with no tolerance for unnecessary weight, wasted energy, or inefficient processes.

Why the Suspended Dump Body Outperforms Conventional Mining Trays

The Suspended Dump Body is the embodiment of decades of applied engineering expertise, field research, and a commitment to solving real-world inefficiencies. From the mines of South Africa to the coalfields of Australia, it has proven that innovation in mining equipment can mean smarter, not necessarily heavier or more complex.

Duratray’s guiding philosophy challenges a long-standing industry mindset – that “more steel” equals more strength. Instead, the SDB shows that strategic use of advanced materials, combined with flexibility, can achieve higher performance while reducing stress on trucks, operators, and budgets.

The Power of a Radically Different Design

Most conventional steel trays are rigid shells that endure impact without adapting to it. This means that every tonne of material dropped from a loader transfers its energy into the structure, generating vibration, shock, and accelerated wear. Duratray took a different approach – asking, what if a dump body could flex?

By combining a high-strength steel frame with a suspended, multi-layered rubber and composite lining, the Suspended Dump Body actively absorbs and dissipates impact energy. This design functions more like a shock-absorbing suspension system than a static steel container. The result is less damage, fewer stress fractures, and a significantly longer working life.

This approach stems from Duratray’s philosophy that adaptation leads to durability – a principle validated by countless hours of field performance data. Mines in high-impact loading environments, such as hard rock operations, have reported dramatic reductions in structural maintenance after converting to the SDB.

Lighter by Design, Stronger by Science

Duratray’s SDB reduces tare weight by 10–20% compared to traditional steel bodies, thanks to its composite materials and rubber lining. This seemingly modest weight reduction creates multiple operational advantages:

- More payload per haul – Mines often achieve 5–10% higher payloads without breaching OEM limits

- Lower fuel consumption – Diesel savings of up to 15% in certain operations translate into hundreds of thousands in annual savings

- Reduced carry-back – The non-stick lining lowers carry-back from 20–35% in some steel trays to below 2%, keeping payloads consistent and fuel use efficient

In one coal operation in Queensland, the mine reported an additional 1.2 million tonnes hauled in the first year after adopting the SDB, without increasing truck hours or fleet size. This kind of result reinforces Duratray’s philosophy that better design improves throughput without overburdening resources.

Built for Real Conditions, Not the Drawing Board

Mining is brutal on equipment – abrasive ore, extreme climates, rough haul roads, and relentless schedules. Many designs work well in theory but fail under this constant assault. Duratray’s philosophy is to engineer from the field back to the drawing board, ensuring that every design choice has been proven under real-world stress.

The suspended rubber lining not only absorbs shock but also protects the steel framework from direct impact, drastically reducing the risk of dents, cracks, and weld fatigue. The modular mat system allows for section-by-section replacement – avoiding long downtime for welding repairs.

In a copper mine in Chile’s Atacama Desert, trays faced severe fatigue from both high drop heights and extreme heat. Standard steel trays required major weld repairs every 18 months. Since adopting the SDB, the mine has extended maintenance intervals to over 36 months, with most interventions involving quick liner repairs rather than full tray shutdowns.

Engineering that Protects People, Not Just Payload

Duratray’s philosophy has always extended beyond mechanical performance to human safety and comfort. Mining truck operators face long shifts in environments where vibration, noise, and jolts can take a physical toll.

The rubber-lined SDB drastically reduces vibration transmitted to the cab, cutting whole-body vibration exposure – a known cause of musculoskeletal injuries. Noise levels can drop by over 5 decibels, easing operator fatigue and improving concentration.

From a safety standpoint, the lighter tare weight and optimised load distribution lower the centre of gravity, reducing rollover risks on uneven haul roads. Combined with the reduced likelihood of spillage thanks to the non-stick lining, these improvements contribute to fewer incidents and better workforce wellbeing.

Lower Lifetime Cost, Greater Long-Term Value

Duratray is clear – the SDB is not designed to be the cheapest tray on the market. Its philosophy prioritises total cost of ownership over headline purchase price.

Savings accumulate in:

- Reduced diesel use

- Longer tyre and chassis life

- Less structural repair downtime

- Higher fleet availability

In a Western Australian iron ore mine, cost modelling showed that replacing the steel trays with SDBs would recover the capital outlay within 18 months through fuel savings alone – with additional gains from increased payload and reduced repairs.

Tailored Precision for Each Mine

Duratray applies its philosophy of precision engineering to every unit it delivers. No two SDBs are identical – each is customised based on:

- Ore characteristics

- Climate and altitude

- Haul road design and gradient

- Fleet make and model

- Specific operational goals

For example, a gold mine in West Africa operating in high humidity and clay-heavy ore conditions required a lining formulation resistant to both stickiness and thermal degradation. Duratray delivered a custom solution that reduced carry-back to under 1%, even in the wet season.

Compatibility is never an obstacle – SDBs fit all major OEM trucks, including Caterpillar, Komatsu, Liebherr, Volvo, and BelAZ, ensuring easy integration into existing fleets.

A Smarter Future for Haulage

Mining faces unprecedented pressure to reduce environmental impact while increasing output. Duratray’s Suspended Dump Body offers a proven path forward – delivering measurable improvements in fuel efficiency, payload, safety, and maintenance.

The SDB embodies a philosophy where every design choice must serve an operational purpose. This thinking has turned what was once considered a simple piece of steel into a high-performance asset that helps mines achieve both financial and sustainability goals.

Frequently Asked Questions (FAQ)

Q1: What is a Suspended Dump Body in mining?

A Suspended Dump Body is a mining truck tray that combines a high-strength steel frame with a suspended rubber and composite lining, designed to absorb impact, reduce weight, and improve payload efficiency.

Q2: How does a Suspended Dump Body reduce diesel consumption?

Its lighter design reduces tare weight, allowing trucks to carry more material with less effort. This lowers engine load, resulting in fuel savings of up to 15%.

Q3: Which OEM trucks are compatible with Duratray’s Suspended Dump Body?

The design is compatible with all major OEMs, including Caterpillar, Komatsu, Liebherr, Volvo, and BelAZ, ensuring flexibility across mixed fleets.

Q4: How long does a Suspended Dump Body last compared to a steel tray?

Field reports show SDBs lasting two to three times longer than conventional steel trays, depending on site conditions and maintenance practices.

Q5: Does a Suspended Dump Body require special maintenance skills?

No. Maintenance is simplified through modular liner sections, allowing quick patching or replacement with standard tools – reducing reliance on heavy welding.

See also When Every Load Matters: Smarter Dump Bodies Are Quietly Changing Mine Safety as well as New fleet of SDBs for one of Canada’s largest diamond mines and Duratray SDB models for CATERPILLAR 796AC mining trucks

The performance data and case studies referenced are from specific operational trials. Actual results may vary based on site conditions, material characteristics, and equipment configuration. This information is for illustrative purposes and does not constitute a performance guarantee. It is the responsibility of the reader to conduct their own technical assessments with Duratray and validate the suitability and safety of any equipment for their specific application. Duratray International disclaims all liability for reliance on this information.