Engineered for Performance, Efficiency, and Versatility

The Duratray Suspended Dump Body (SDB), is a unique lightweight tray whose design has demonstrated a wide range of benefits catered to specific mine and quarry applications, including abrasion resistance, payload increase, carryback reduction, less maintenance cost, OH&S improvement to operator, load-shock absorption and significant noise reduction across the mine operation, making it an environmentally friendly equipment.

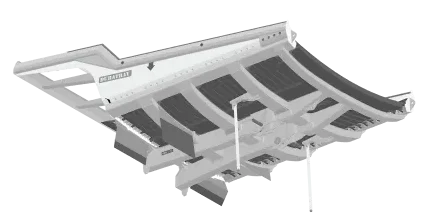

This design concept replaces the conventional steel floor, as well as any associated wear plates with a rubber mat suspended on elastomeric ropes anchored to the steel frame of the body. Suspended Dump Bodies are lighter in weight and have higher volumetric capacity than standard steel floor designs. The SDB are installed on 30 to 360 tonnes trucks across all major OEMs, including Komatsu, Caterpillar and Hitachi.

Global Performance, Proven Reliability

Trusted Worldwide with 3,000+ SDBs in Action Across 38 Countries.

There are currently more than 3,000 SDBs in operation in 38 countries worldwide with a high level of acceptance in large-scale open-pit mineral mines such as bauxite, coal, copper, diamonds, nickel, gold, and iron ore.

SDBs can be used in haulage environments such as large mines, quarries, and underground sites.

Suspended Dump Body (SDB)

Customised Design

Built to outlast and outperform

- Canopy Liner

- Side Liner

- Wearmat

- Load Protection System (LPS)

- Undermat

- Suspension Ropes

Did You Know...

The world’s largest electric vehicle is a dump truck with a Duratray SDB.

Duratray’s Suspended Dump Body has resulted to be the perfect match for the first environmentally friendly lithium-ion powered truck operating in Switzerland since January 2018. Find out more about our Green Tray.

Comparative Characteristics

The level of adhesion carryback of the transported rocks

This factor significantly reduces the downtime of dump trucks under the forced mechanized cleaning of the body from adhered rock.

Up to

3%

SBD

Up to

35%

OEM

Extended Maintenance Intervals

Increased resistance to abrasive wear – increased overhaul intervals.

Months

35-40

SBD

Months

9

OEM

Reduced Maintenance Downtime

The rope tightening, tray inspections and bin liner replacements where necessary are very quick in comparison with the maintenance of traditional Steel trays. This translates to increased productivity and profitability for mines.

Working Days

1-2

SBD

Up to

6 Weeks

OEM

Reduced fuel consumption and tire wear

It is achieved by reducing the level of adhesion and reducing the weight of the body.

18%

SBD

SDB body does not require an additional metal lining

SDB is 7-10% lighter than OEM (steel body), which results in an increase in dump truck load capacity by up to 20%.

Payload capacity increased by

20%

SBD

Special body structure

The special body structure allows to reduce shock loads on the dump truck frame during loading operations by 40%

Factors influencing ergonomics

Factors affecting the ergonomics of work during loading and unloading operations: reduction of the compression load on the spine of the dump truck operator by 40% and the noise level by 15% (by 14dB).

Health & Safety of Operators

The Duratray Suspended Dump Body (SDB) delivers notable safety benefits in mining by reducing Whole Body Vibration (WBV) and noise exposure.

Its flexible rubber mat acts as a shock absorber, cutting vertical impact g-forces by up to 50%. This results in a smoother ride and less stress during loading.

In trials, vibration levels with the SDB measured 0.259m/sec², compared to 0.611m/sec² for a steel body (so, the Duratray SDB reduces vibration by approximately 57.6% compared to a steel body), extending the operator’s safe exposure time from 5.38 to 29.81 hours under EU guidelines.

This is significant — the Duratray SDB extends the operator’s safe exposure time by approximately 454%, compared to a standard steel body.

At Mt Keith, the SDB cut vibration by nearly 50% during loading.

The SDB also reduces noise by up to 10 decibels. In-cab noise fell by 5.5 dB(A) — from 92.3 to 86.8 dB(A) — after SDB installation. Other sites also reported lower sound levels during loading.

A Quieter, Less Stressful Ride

The Duratray Suspended Dump Body (SDB) also helps reduce noise — both outside the truck and inside the operator’s cab. After installing the SDB, in-cab noise dropped by 5.5 decibels, going from 92.3 dB(A) down to 86.8 dB(A).

That may not sound like much, but decibels work on a logarithmic scale — so this change means the noise inside the cab was cut by around 64% in terms of perceived loudness.

Less noise means less fatigue, better focus, and a safer working environment for the operator.

Reduced Carryback for Safer Operation

Another safety gain comes from the SDB’s ability to greatly reduce or eliminate carryback, removing the need for additional equipment or manual clearing.

Improved Equipment Protection and Reliability

Reduced vibration further protects truck components, improving reliability and lowering breakdown risks.

Suspended Dump Bodies (SDB)