Duratray

Products

Designed to Perform

Customised designs engineered to outlast, outperform, and elevate your operations.

Innovative Solutions, Proven Performance.

As the leading designer and manufacturer of dump bodies, Duratray delivers cutting-edge technology for mining applications.

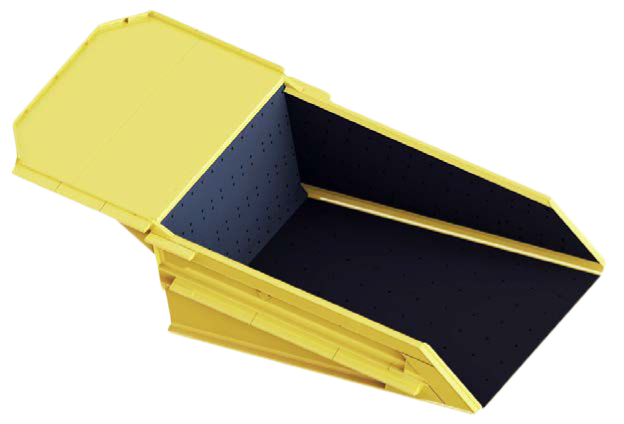

The Suspended Dump Body (SDB), Duratray’s flagship product, features a lightweight design with a flexible rubber wear mat supported by high-capacity synthetic suspension ropes and an abrasion-resistant steel frame. This innovative design provides numerous benefits tailored to mine and quarry operations, including increased payload capacity, reduced carryback, and noise reduction.

As a hybrid dump body, the SDB combines the best of steel and rubber to offer a light-weight equipment designed to increase payload, decrease carryback and reduce noise.

Products

Designed to Perform

Customised designs engineered to outlast, outperform, and elevate your operations.

We offer a comprehensive range of applications designed to meet the toughest industry challenges, providing customised, high-quality, and cost-effective solutions that enhance overall productivity. Our solutions address key issues such as abrasion resistance, payload increase, carryback reduction, lower maintenance costs, improved OH&S for operators, load-shock absorption, and significant noise reduction, ensuring optimal performance across multiple sectors.

Innovation in Motion,

Designed to Perform.

Duratray’s Suspended Dump Body (SDB) redefines mining efficiency with its innovative design. It eliminates carry back, increases payloads by 20%, reduces noise by up to 10 dB, and cuts abrasion by 65%. Offering superior shock absorption and low maintenance costs, the SDB delivers unmatched performance and durability.

What the Industry’s Best Say About Us

Endorsed by Experts, Trusted by Clients

Duratray International is known for practical innovation and proven results. See what our clients, expert team members and partners have to say about working with us.