Versatile Protection. Built to Last.

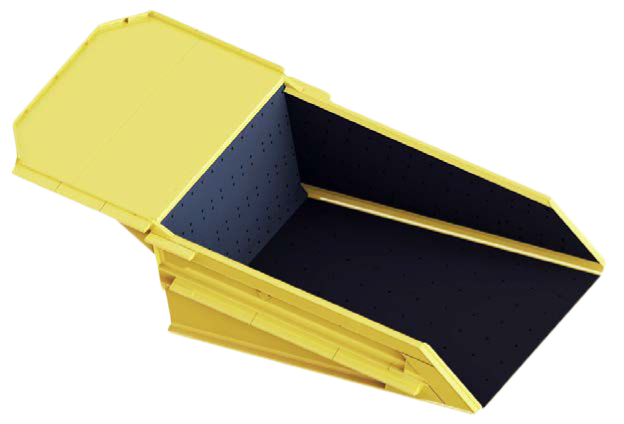

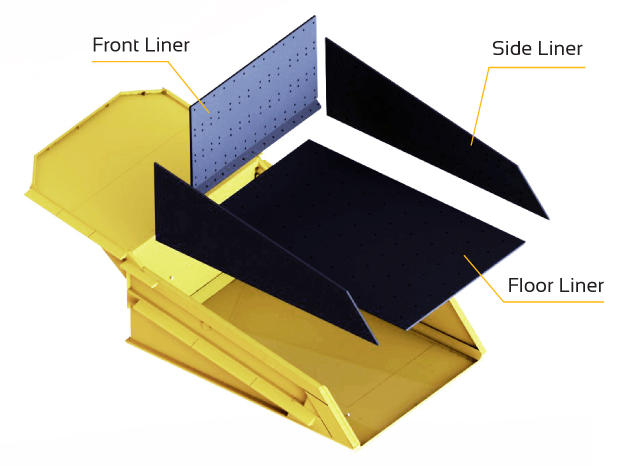

Duratray Rubber Liners are engineered to extend the life of equipment by protecting metal surfaces from wear, impact and abrasion. While they are most commonly used in mining dump bodies, their application goes far beyond trays.

Rubber liners can be installed as a full package—covering the floor, canopy, front and side walls—or as a partial package, depending on the wear pattern and operational needs. Whether it’s a full or partial fit-out, the result is the same: longer service life, reduced maintenance, and improved operational uptime.

But dump bodies are just one of many possibilities.

Duratray Rubber Liners are used across both mobile and fixed equipment, including:

- Chutes, hoppers and bins

- Buckets, tanks and trailers

- Barges and rail cars (transport)

- Trash compactors and shredders (waste & recycling)

Durable, adaptable, and easy to install, Duratray Rubber Liners offer superior protection in some of the world’s harshest environments. Whether you’re in mining, construction, transport or waste management -Duratray’s liner technology keeps your operations running smoother for longer.

Duratray

Rubber Liners

Improved Operator Health & Safety

Vibration Dampening

The rubber mat plays a key role in cushioning shock and lowering Whole-Body Vibration (WBV) by up to 50%, greatly increasing safe exposure time for operators.

Lowering WBV by up to

50%

increasing safe exposure time

Noise Reduction

As part of the SDB system, the mat helps reduce in-cab noise by up to 10 dB, creating a quieter and more comfortable working environment.

Reduce noise by up to

10dB

in the cab

Reduced Truck Stress

The shock-absorbing qualities of the rubber mat reduce impact loads transferred to the truck’s frame, suspension, and tyres – a benefit amplified by the SDB’s lighter overall design.

Reduced

Impact loads

to the frame, suspension & tyres

Efficiency Gains Through Integrated Design

Increased Payload

The rubber mat contributes to the SDB’s lightweight construction – up to 40% lighter than conventional bodies – enabling significantly higher payloads. Some mines have recorded increases of up to 30%.

Up to

30%

Increase in Payload

Fuel & Emissions Savings

The combined effect of no carryback and greater payload capacity results in fewer trips and lower fuel consumption, directly supporting cost savings and decarbonisation goals.

Spillage Control

The SDB’s well-balanced design and rubber floor help contain different material types with reduced spillage, supporting cleaner, more efficient operations.

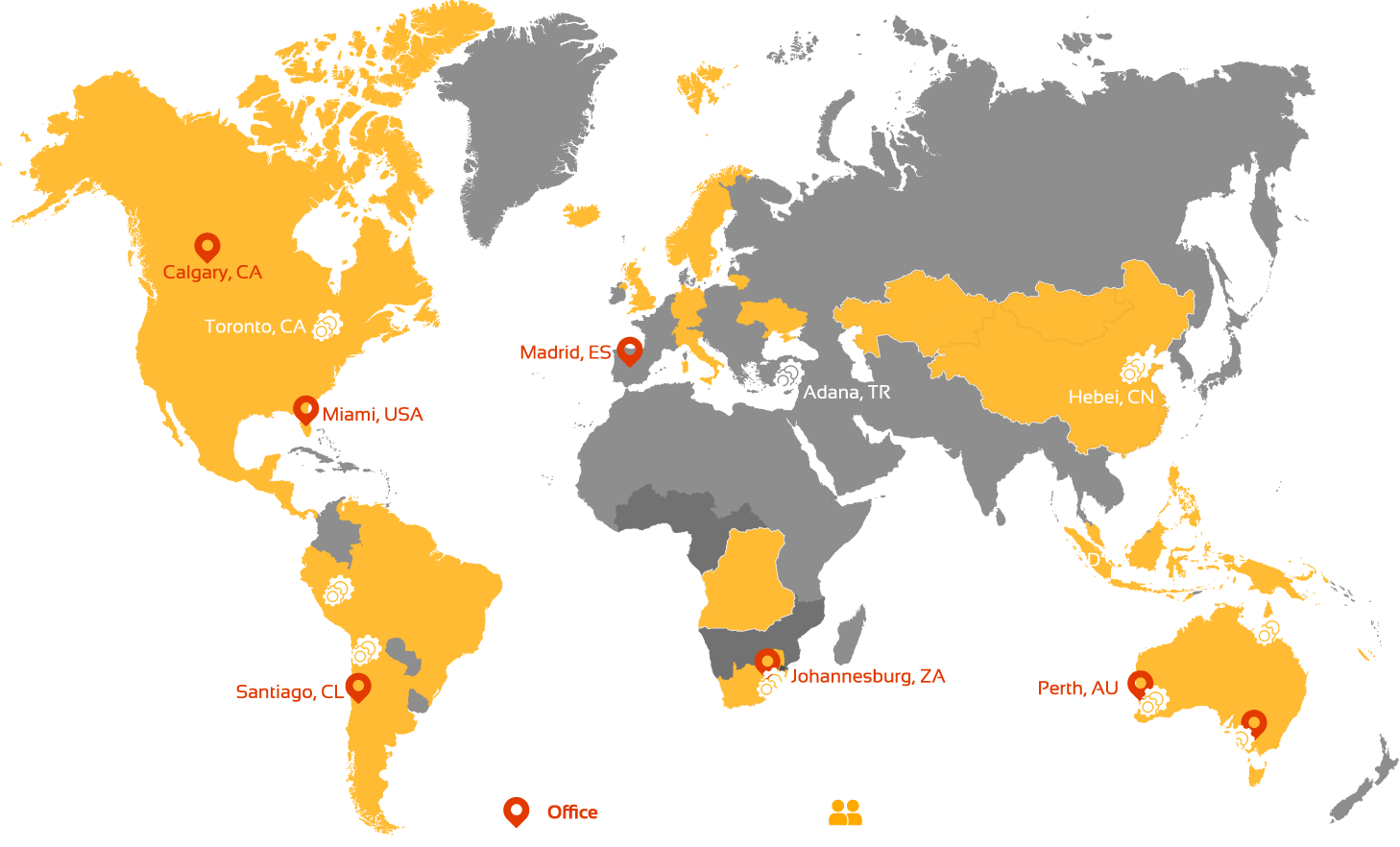

Global Operations

Innovation World-Wide

Duratray delivers innovative haulage solutions to operations world-wide.

Duratray International operates across six continents, with offices, fabrication facilities, and customer locations strategically positioned to serve various industries worldwide. From the Americas to Asia, Africa, and beyond, our presence ensures innovative solutions are delivered to some of the most remote and challenging regions, including Kazakhstan, the Arctic, and Indonesia.

Continents

Countries